-

Metallurgical industry

We offer tailor-made services with a single interlocutor and our Extensive experience in the metallurgical sector has made us a reference supplier in companies of the entire national territory.

Ask for information

In addition to renting equipment to gain flexibility, many companies have their own machinery park that works intensively in an aggressive environment. GAM takes care of the management and maintenance of machines or entire fleets with cost control. GAM has specialist technical staff to provide service at the customer's facilities or in its own offices. GAM's maintenance plans prevent breakdowns and outages, which means greater safety, higher productivity and considerable savings on repairs.

GAM's service includes replacement machines, 24/365 technical support, certified training on machinery handling, spare part sales, RD 1215/97 compliance and permanent mechanical service available at the customer's facilities.

Internal logistics automation is a recurring challenge for large as well as small companies. Automating material transport and other repetitive and high-frequency tasks enables metal companies to optimise productivity. The ability to schedule deliveries more effectively reduces bottlenecks in production and streamlines finished product distribution.

We are specialists in services related to machinery and we are in constant contact with our clients in order to provide added value to their main activity.

We offer a comprehensive rental service, complemented by maintenance, training and purchase-sale.

We also have business lines specialized in drone engineering, AGVs, modular structures, machinery distribution and event production for companies.

Our projects include turnkey energy plans, fleet optimization with carbon footprint analysis, machinery fleet management, fleet monitoring, technical studies for warehouse improvement and create cleaner work environments, process automation and robotization.

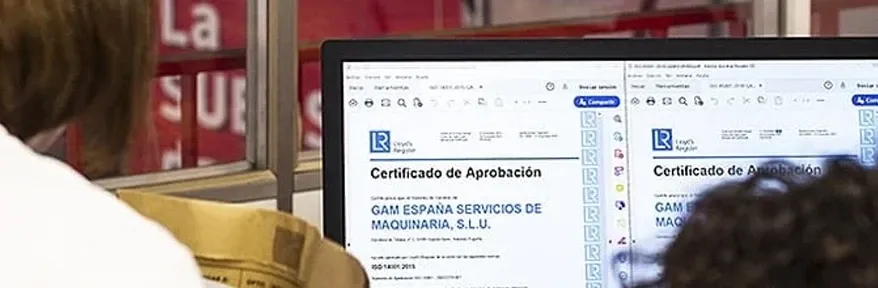

As part of our commitment to safety and the environment, GAM voluntarily submits to different audits and quality controls. The company is accredited with international standards ISO 9001, 14001 and 45001, highest accreditations in Prevention, Safety and the Environment. 75 delegations, 600 technicians and more than 300 mobile workshops.